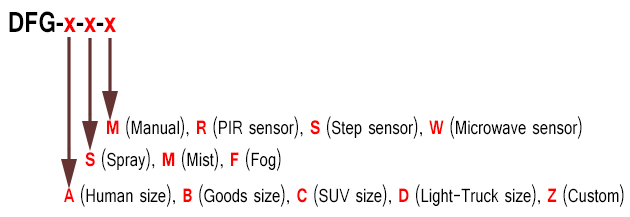

DISINFECTION FOG GATE

انفاق التعقيم أو بوابات التعقيم (بالعربي)

Contents:

#Applications . #High vs Low pressure . #Features . #Technical data . #Costcalculator . #Selection . #Customization . #How it works . #FAQ’s

Some disinfection tunnels or gates have poor efficiency:

We have seen recently videos from several locations, showing some variations of disinfection fogging gates or passages. Some had very few nozzles to cover all person or goods, and some seems to use normal low-pressure pumps in the range of 10bar. Those pumps actually spray bigger particles with poorer coverage. While high-pressure fogging pumps produce dense (5-20 microns) particles that stay mostly suspended in air. High-pressure fog clearly offer dense coverage, less waste and less wetness.

The next photo showing the most differences you would expect if decided to use low-pressure, 20 nozzles installed on each.

The cost of low-pressure solution is much less than high-pressure one, but the disinfectant waste is much more to achieve same coverage.

FEATURES:

- Fully automatic and equipped with sensors.

- No need for supervision.

- High pressure fogging.

- Excellent coverage.

- Well spread without dead-zone.

Technical data:

Consumption *

DFG-A-F-x (recomm ended) | Fogging 30-70 bar(~1000 PSI) | ~100 ml | Dual Pump Booster pump + Fogging Pump |

| DFG-A-M-x | Misting 11-29 bar (~350 PSI) | ~270 ml | Single Pump |

| DFG-A-S-x | Spraying 4-9 bar (~100 psi) | ~600 ml | Single Pump |

* Estimated based on 4 seconds exposure in normal conditions

Economical / well designed for minimum consumption with maximum coverage.

Fogging disinfectant cost calculator

| Material | Coated Aluminum frame, white With strengthen coated iron corners | |

| Sides (DFG-A-x-x-x) | Transparent safety acrylic sheet | |

| Sides (DFG-A0-x-x-x) | Nylon sheet | |

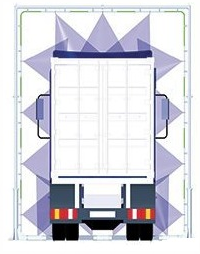

| Sides (DFG-C/D/Z-x-x-x) | Metal / Aluminum / HPL Sheets options For Cars and trucks Gate | |

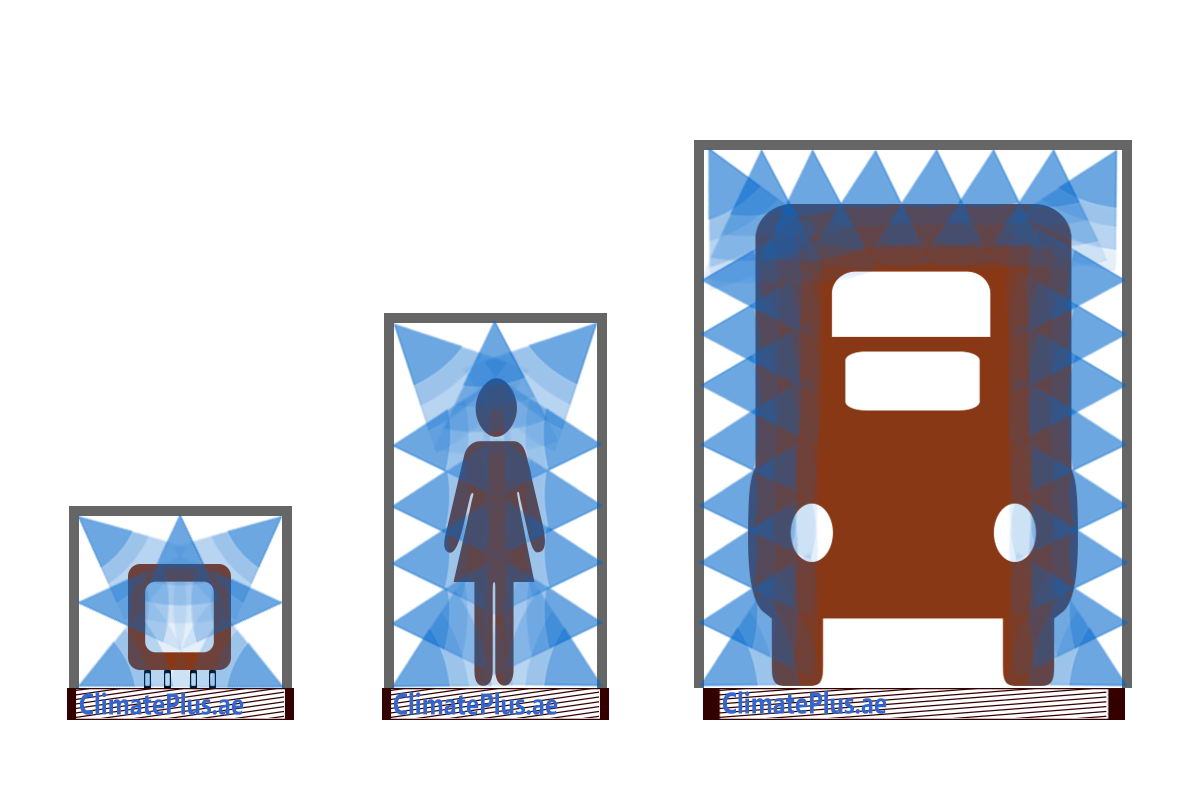

| Dimensions (LxWxH)cm | DFG-A-x-x (127x100x220) (Human) disinfection fog gate DFG-B-x-x (381x100x220) (goods)- Disinfection fogging camper DFG-C-x-x (127x250x250) SUV – car- pickup fogging gate DFG-D-x-x (127x300x300) for light trucks up to 3ton DFG-Z-x-x /custom for trucks and roads* | 20 nozzles 6 nozzles 60 nozzles 100 nozzles Up to 160 nozzles |

| Material | Seamless SS tube or High-Pressure Flexible option |

| Size (inch) | 3/8” 9mm or 8mm |

| Rated pressure (bar) | 100bar / 2000 psi |

| Material | Nickel plated |

| Rated pressure (bar) | 150 |

| Bore size (mm) | 0.2 |

| Connection (inch) | 10/24 |

| Filtration | Integrated nozzle filter, cleanable (only DFG-x-F-x) |

| Rated voltage (VAC) | 220-230 |

| Power (W) | DFG-x-S-x (80-150W)

DFG-x-M-x (160-600W) DFG-x-F-x (800W-1500w) |

| Working pressure (bar) | DFG-x-S-x (<10)

DFG-x-M-x (10-29) DFG-x-F-x (30-70) |

| Max pressure (bar) | DFG-x-S-x (9)

DFG-x-M-x (29) DFG-x-F-x (80) |

| Capacity (LPM) | DFG-x-S-x (4-12LPm)

DFG-x-M-x (2-6LPM) DFG-x-F-x (0.3-4LPM) |

| Estimated particle size (um or microns)

(using C+ 0.2 nozzles) | DFG-x-S-x (40>)

DFG-x-M-x (15-30) DFG-x-F-x (5-14) |

**(DFG-x-M-x) & (DFG-x-F-x) may require additional booster pump to deliver liquid supply to high-pressure pump from a tank.

| Operation sensor | DFG-x-x-M (Manual button, No sensor)

DFG-x-x-R (PIR sensor) DFG-x-x-S (Step sensor) DFG-x-x-W (Microwave sensor) |

| fogging time | Adjustable |

Optional, Not included by default

Model Selection

Note: Human size gate default sides are safety acrylic sheets DFG-A, available with less expensive Nylon version DFG-A0 on request only

Customized sizes and materials as per request, please contact us.

How It Works

The disinfectant eco-friendly liquid is combined with water to create a fog, using special pumps, with an adjustable particle-size, so that it will cover the maximum surface area of any object or person and can designed for your required purpose.

General:

1. Have you installed the disinfection tunnel in UK and who are your present clients? We have client like London municipality, Farnek, Servue, Al futtaim, SEWA and many more.

2. Is the Disinfection chamber recommended by London Government? We are the approved supplier by London municipality.

3. Is the disinfection chamber suitable for office suits or its only suitable for hospitals and clinics disinfecting with HAZMAT suits? Depends on which disinfectant chemical you are using.

4. Is it mandatory to wear face mask, gloves and goggles to enter the disinfection chamber and minimize the exposure to skin? Depends on which disinfectant chemical you are using.

5. Is the equipment available on a rental basis? Yes, but minimum of 1 month

6. How effective is this disinfection towards COVID-19 virus? It depends on disinfectant chemical you are using.

7. Will you be able to arrange a site visit to check this equipment in operation? yes

8. Is this disinfection spray will make your cloths moist? Only if you take low pressure high volume system. We are selling pure fogging system which is high pressure low volume. On an average low pressure high volume system consumes 500 to 700 ml of liquid/ person while a high pressure low volume system consumes 100 to 150 ml of liquid/person only.

Design:

1. If there are 2500 office users / staff and if they must reach their work desk in 1 hours. How many tunnels o you recommend? Give us your technical details to substantiate with design and length of the dis-infection chamber required. In a normal size tunnel every 3 second you can pass 2 persons. And a normal gate takes 3 second to disinfect 1 person. Hence for tunnel you need minimum of 2 tunnels and for gate you need 3 to 4. For 2500/hr

2. What is the time needed to install a disinfection chamber? 5 working day to manufacture and 2 days for installation on site

3. Is there any drainage system required in the dis-infection chamber for collection of residual liquid mist sprayed? You might have to clean the floor after every 15 to 20 minute to make sure the floor is not too wet.

4. Any technical training required for the daily operation? None

5. Do you need an operator to be on standby continuously? Our system comes with sensor, hence you don’t need any operator.

6. Will you provide the training for the dilution of chemical and how to store it? Yes we can guide you

7. What is the per hour consumption of disinfection liquid as per the design based on nozzle selection? 100 ml to 150 ml/ person

8. How will you ensure the uniformity of the spray in the chamber? Fog will be uniform as it comes from 0.2 mm size of nozzles

9. How much stock we need to keep for a month / site? Depends on your usage

10. Do you need plumbing for automatic dosing system? Is this in your scope? We don’t do it

11. Are the spare parts available for the replacement locally in UK? Yes we have the availability of all spare parts

12. Can the Disinfection tunnel be installed in an open sunlight area? Yes, but recommended to provide shade

Technical:

1. What is the chemical used in dis-infection tunnel? Any chemical approved by London municipality

2. Do you support after sales service? Yes we can

3. Do you have the proof of its effectiveness? N/A as related to disinfectant used. However, we designed to provide dense full fog coverage as our videos show compared to others we seen on multiple occasions.

4. Is this equipment portable / movable to new locations? Not movable

5. What is the power requirement for the Unit? 2Kw

6. Is there any periodical maintenance required in the operation of the equipment? Cleaning of nozzles and tank every month for better performance

7. Do we need an Operator required for monitoring the operation? no

8. What is the concentration of the chemical used? Depends on the chemical you select

9. Do you supply the chemicals required or we need to outsource from the market? Yes we can, and can guide you

10. If the chemicals need to be outsourced, do you have any preferred vendor that you recommend? Yes we do

11. What is the concentration required for the disinfection? Is that concentration safe for Humans? Yes it is safe and concentration varies as per the chemical selection

12. Is it safe to use it on the people with prior skin allergies? It depends on the chemical you are using

13. Will it be safe to use with peoples not wearing mask or goggles? It depends on the chemical you are using

14. Is it safe to use for people wearing contact lens? yes

15. Is it safe for the pregnant ladies to pass through the disinfection chamber? yes

16. If we buy chemicals from other vendors does it create any problem in the equipment operation? No

17. What is the PH value required for the water to make the solution? Can we use the Normal DEWA water for mixing and dilution of chemical? Concentration depends on the chemical you are using, you can use the DEWA water also

18. What are the safe storage guidelines for the chemical? Can it be stored open to sky? Yes mostly. Chemical supplier would help to confirm

19. Is the chemical normally stable at room temperature? yes

20. Are disinfectant chemicals available locally? yes

21. Is the disinfection chamber recommended by Doctors? This question is valid for the type of chemical you are using.

22. What is the difference between bleach and Hypo chloric acid? We are not chemical manufacturer, we are only supplying chemical from the local manufacturer. If you want we can provide you direct contact of the manufacturer and you can deal with directly

23. Will Dosimeter show us or alert us above the recommended concentration? N/A